Effluent Treatment Plant

Effluent Treatment Plant (ETP) is a crucial component in industries and municipalities for the purification of wastewater before it is discharged.

"Find the right wastewater treatment plant solution for your installation requirements"

Sewage treatment plant manufacturers collect, treat, and release wastewater, offering a service important process for ecological and general health.

Effluent Treatment plant manufacturers is the most common way of removing strong, chemical, and natural substances from the wastewater created by industries.

Water treatment plant manufacturers upgrades the quality of water and makes it appropriate for drinking, cooking, and other different purposes as indicated by the requirement.

Wastewater treatment plant manufacturers are responsible for gathering water from a populated region or industrial area and of removing its pollutants.

Iron removal plant manufacturers is designed in light of oxidation, filtration and Reactant Oxidation filtration so it can eliminate metals and chemical residing in water.

An automatic Water treatment plant manufacturers is an exceptionally proficient and high level system designed to treat wastewater from different sources.

Reverse osmosis plant manufacturers is one of the best, practical innovations that anyone could hope to find for eliminating a scope of contamination from water.

Drinking water plant manufacturers purify water by eliminating unsafe substances that are available in it through a progression of processes.

Contingent upon the kind of unrefined substance got, the plastic recycling WTP plant manufacturers require various measures of washing water to accomplish the ideal level of cleaning.

Dairy ETP plant manufacturers assume a basic part in moderating the unfriendly effects of dairy effluent on the environment and human health.

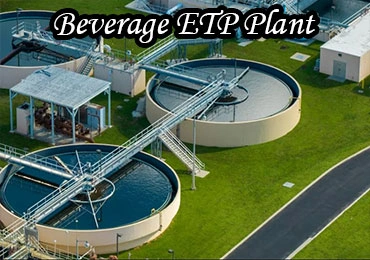

An ETP plant manufacturers interaction for the beverage industry treating wastewater created from beverage production to remove contaminants with ecological guidelines.

Wastewater Recycling Plant manufacturers especially fit to concentration plants where tailings are dewatered, and water utilization is moving to short reuse water streams.

"No.1 Company in serving Water Treatment Plant. Work with the Best!"

"There are some commonly asked questions relative to water quality within a plant".

A Sewage Treatment Plant (STP) is a facility designed to treat and remove contaminants from wastewater, typically from domestic or industrial sources, making the water safe for reuse or discharge into the environment.

Most STP manufacturers offer a range of services, including:

Design and engineering of STP systems

Supply of STP machinery and components

Installation and commissioning

Operation and maintenance (O&M)

Upgradation and retrofitting of existing plants

Activated Sludge Process (ASP): Common biological treatment using aeration and microorganisms.

Moving Bed Biofilm Reactor (MBBR): Compact and efficient biofilm-based technology.

Sequential Batch Reactor (SBR): Treats sewage in batches, allowing flexible operations.

Membrane Bio Reactor (MBR): Combines biological treatment with membrane filtration.

Hybrid Systems: Tailored for space and efficiency needs, combining technologies.

Experience & Certifications: Look for ISO or government-approved vendors.

Customization: Can they design systems specific to your site's needs?

After-Sales Support: Ask about maintenance contracts and response times.

Client Portfolio: Check references and previous installations.

Environmental Compliance: Ensure solutions meet local and national discharge norms.

Yes, many offer end-to-end services including:

Site survey

Design and engineering

Equipment supply

Installation and commissioning

Training and documentation

Lifespan: Typically, 15–25 years with regular servicing.

Maintenance: Requires routine checks, sludge removal, filter cleaning, and aeration system servicing.

STP capacity depends on the daily sewage generation, usually calculated based on the number of users (e.g., residents, employees) and water usage. Manufacturers typically help assess your requirements and recommend the appropriate capacity.

Yes, according to pollution control board regulations in many states, installing an STP is mandatory for residential townships, apartment complexes, hotels, hospitals, commercial buildings, and industries generating a certain volume of wastewater.

Compliance with environmental laws

Reduction of pollution and odour

Water reuse for gardening, flushing, and cooling

Sustainable waste management

Reduction in water bills

Regular maintenance includes:

Checking and cleaning filters and membranes

Monitoring biological processes

Sludge removal

Inspection of pumps and blowers

Maintaining proper aeration and chemical dosing

Yes. All systems are designed to meet CPCB and SPCB norms and effluent discharge standards. Manufacturers often customize designs based on local regulatory requirements.

Effluent treatment (ETP) plants manufacturers in Chennai remove industrial effluents and contaminated water from exit pipes, supplies, rivers, and lakes, among different places, and reuse the water resource for various uses. Textile, pharmaceutical, leather, and chemical industries are among the industries where ETP plant manufacturers in Chennai are regularly used. Such a Industrial Effluent Treatment Plant manufacturers in Chennai guarantees that contaminated and polluted industrial water is treated and made reusable previous to being delivered once again into the environment. People will not be able to get ideal, functional water for family purposes without this treatment.

Effluent Treatment Plant (ETP) Suppliers in Chennai is a significant part of the manufacturing system with regards to wastewater, the site's sewer/drainage system, and the contaminants with their comparing limit regards that should be met. Moreover, the ETP plant design consultant in Chennai helps with the decrease of the amount of release places in a industrial home, allowing eco-friendly administrative bodies to all the more likely accomplish contamination decrease and environmental increases. The treated industrial wastewater (or effluent) can be reused or released into a clean sewer or into the environment's surface water.

Sewage treatment plant manufacturers in Chennai assume a requirement part in maintaining general health, protecting the environment, and guaranteeing economical water resources. We will excavate into the universe of sewage treatment, examine what sewage is, the manner by which STP plant manufacturers in Chennai ability step by step, and examine the condition of sewage treatment plant construction in Chennai. Sewage is a term used to describe the wastewater and waste materials that are created from different human activities, including residential, industrial, and commercial sources.

Dairy Sewage treatment plant in Chennai is a efficiency designed to treat and clean wastewater before it is delivered into the environment. The requirement objective of sewage treatment plant is to remove unsafe contaminants and toxins from the wastewater, making it alright for release or reuse. Industrial sewage treatment plant manufacturers in Chennai assume an essential part in preventing water contamination, safeguarding sea-going biological systems, and guaranteeing a possible collection of clean water.

Wastewater treatment plant manufacturers in Chennai is important to protect our current environment and the health of both people and animals. At the point when wastewater isn't exchanged with as expected, it can contaminate our water sources, damage regular environment, and cause difficult diseases. Actually, Automatic wastewater treatment plants in Chennai do as described; they treat the water that goes down our pipes/channels prior to releasing it back into the environment. No matter what the attempt that are being made to install these plants around the world, more is required. Water is quite potentially of our most important resources and it's being wasted. There are various ways of treating industrial wastewater, and the better the process, the higher the rate that can be reused before it gets unloaded into the sea.

People in general have began to rise up to oil companies about deep oil drilling and wastewater and the guidelines are consistently changing, particularly with consider to simple and its impacts on the environment. It's great that the industry is under a microscope as the more simple that is authorized necessary, the better. We really want to raise the degrees of supposed for oil companies, mines, and other large scope industries as they've been available and offered to the most remarkable applicant for a really long time.

DM Water Treatment Plant manufacturers in Chennai is a physical process. Ion exchange resins are extraordinarily produced which help to replace the mineral salts in water. There are two types of resins- anion exchange and cation exchange resins. The previous resins release hydroxyl particles which are normally harmful charged particles. The cation resins discharge hydrogen particles which are generally definitely charged particles. Industrial Demineralization(DM) is a wastewater treatment process in Chennai which purifies water at comparative degrees of refined water. It is a quick communication which doesn't need increase fabricate. Different standards are continued in the demineralization process - ion exchange, deaeration, and polishing.

With regards to water purification, the particle exchange process is fast and reversible. What's more, one of the demonstrated processes to treat water is the demineralization technology. The parts utilized in each process might shift relying upon the creation of the water which is to be dealt with. Demineralization (DM) water treatment in Chennai process has huge application in the fields of materials, chemicals, boilers feed water, hospitals, pools, pharmaceutical industries, as well as automobile destroy.

Water is a basic resource fundamental for all life on The Earth, and its accessibility and quality are critical for human prosperity and environmental sustainability. Industrial effluent treatment plant project renovation in Chennai assume an essential part in guaranteeing admittance to protected and clean drinking water, making them imperative infrastructure locally. Over the long run, these facilities can become obsolete, wasteful, and unfit to fulfill the developing needs of the population and changing quality guidelines. Because of these difficulties, the effluent treatment plant construction in Chennai has arisen as a basic drive to improve maintainability and safe a solid wellspring of clean water.

ETP plant project renovation in Chennai is much of the time required by a mix of variables, including maturing infrastructure, population growth, advancing guidelines, and developement in innovation. These elements by and large add to the decay of the facilities ability to ideally work. The renovation of industrial effluent treatment plant project in Chennai is a basic step towards getting a maintainable and dependable wellspring of clean water for communities. As populations develop, guidelines advance, and innovation progresses, these facilities should adjust to address industrial challenges.

Industrial sewage treatment plant manufacturers in Chennai assume an imperative part in maintaining general health, safeguarding oceanic environments, and guaranteeing a reasonable future. Notwithstanding, large numbers of these facilities are maturing and battling to stay up with the requests of a growing population and changing ecological guidelines. Remodel projects for sewage treatment plants in Chennai have become basic to address these difficulties and establish a cleaner and safer environment for current and people in the future.

Renovating sewage treatment (STP) plant in Chennai is an essential move toward getting a cleaner, better, and more reasonable future. Sewage treatment plant projects in Chennai address the difficulties presented by maturing infrastructure, population growth, stricter regulations, and environmental change. By putting resources into the renovate of sewage treatment plants in Chennai, we safeguard general health, save the environment, and advance economic growth. It is fundamental that governments, networks, and industries team up to guarantee the progress of these indispensable projects, exhibiting a pledge to protecting our normal resources and advancing a more promising time to come for all.

Utilizing an automatic water treatment plant in Chennai offers various benefits that can decidedly affect both the environment and our regular routines. One significant benefit is the capacity to get wastewater without causing damage the encompassing biological system effectively. These plants utilize trend setting technology and processes to remove contaminants, microbes, and other harmful chemicals from the water before it is delivered once more into quality. This safeguards our rivers, lakes, and seas from contamination, protecting their excellence and guaranteeing a better living space for aquatic life.

Notwithstanding ecological advantages, automatic water treatment plant manufacturers in Chennai likewise add to general safety by reducing the chance of waterborne diseases. By successfully treating wastewater before it enters our drinking water sources or sporting facilities, these plants help with prevent defilement and protect networks. Besides, utilizing an automatic water treatment plant in Chennai can save costs over the long term. Appropriately treated wastewater can be reused for water system purposes or industrial processes as opposed to depending exclusively on freshwater resources.

The demand for bottled mineral water is expanding as people are turning out to be more health aware. It contains huge amounts of minerals and gases. It comes from underground saves and isn't chemically handled. Minerals that are many times present in mineral water are calcium, magnesium, potassium, sodium, bicarbonate, iron and zinc. Mineral water is bottled at the source dissimilar to tap water and goes through filtration and broad treatment to accomplish the most elevated level of purity in a mineral water bottling plant in Chennai with bottle packaging. Care is likewise taken while packaging mineral water with the goal that no pollutants can disintegrate water quality.

As manufacturers of mineral water bottling plants in Chennai, we have made systems that capability perfectly together. We additionally give an unparalleled variety of Mineral Water Treatment in Chennai and Packaging equipment as providers. Mineral water bottling plant in Chennai is a facility designed to purify, package, and circulate mineral water for commercial deal. The process regularly includes a few phases, including water treatment, filtration, sterilization, bottling, and packaging.

Commercial RO Plant manufacturers in Chennai is a water decontamination plant that works Reverse Osmosis Technology (RO) for the removal of pollutants from water. A 2000LPH Commercial RO Plant in Chennai helps with eliminating the disintegrated impurities and destructive chemicals for giving just clean water. Commercial RO Plants in Chennai are extraordinarily designed for creating water at an enormous scope, ok for utilization and to reduce the gamble of water-borne diseases. A Industrial RO Plant Manufacturers in Chennai has various filtration stages. A SS RO Plant Manufacturers in Chennai utilizes a semi-permeable layer, which is likewise the core of the RO Plant installation in Chennai, to sift through the impurities. The raw water under high pressure is constrained through a semi-permeable layer, where contaminants are isolated from the water, abandoning unadulterated water.

A Commercial RO Plant or any Reverse Osmosis Plant in Chennai deals with the rule of Reverse Osmosis. In RO or Reverse Osmosis Plant in Chennai broke down solids present in water are taken out through the course of actual separation. Commercial RO plant in Chennai additionally involves pre-filters and post-filters for pre-treatment and post-treatment of pollutants in water. Different industrial areas like the food industry, material, pharmaceuticals, and so on need unadulterated water for their items. A Commercial RO Plant in Chennai eliminates overabundance chemicals which can hurt people as well as machines. Commercial RO Plants in Chennai help industrial/commercial as well as at home.